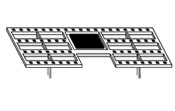

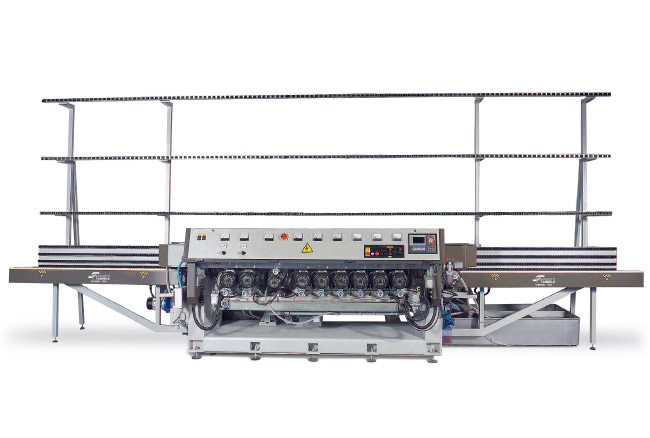

Straight bevelling machine

for the processing of bevels from 0° to 45° – with cerium oxide polishing

- Conveyor–track composed of rubber pads with six bearings, fixed to a chain that glide along steel guides

- Automatic lubrication system

- PLC touch screen to adjust thickness, working speed, mitering system and to input and display all the working parameters and diagnosis of faults

- Independent adjustment of diamond wheels

- Automatic adjustment of polishing wheels

- Double speed motors for polishing wheels

- A series of ammeters display loads on motors

- Close–circuit water cooling system

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

Especially suitable to medium/big glass companies for the production of mirrors, furniture and interiors

Datasheet

| thickness ranging | 3/20 mm | |

| minimum dimension | 80x80 mm | |

| max load | 800 Kg | |

| height of work surface | 960 mm | |

| total capacity | 11,2 kW | |

| tank capacity | 477 l | |

| air consumption | 250 Nl/min | |

| forward speed | 0,6/3 m/min | |

| overall weight | 4.660 Kg | |

| variable angle | 0°- 45° |

| thickness ranging | 3/25 mm | |

| minimum dimension | 80x80 mm | |

| max load | 800 Kg | |

| height of work surface | 960 mm | |

| total capacity | 14,2 kW | |

| tank capacity | 477 l | |

| air consumption | 250 Nl/min | |

| forward speed | 0,6/3 m/min | |

| overall weight | 5.142 Kg | |

| variable angle | 0°- 45° |