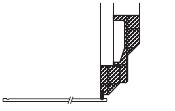

Vertical milling and drilling machines

for the execution of holes and notches

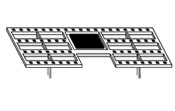

- The machine consist of 3 independent sections

- OPEN TOP structure

- Completely automated

- The user interface is a wide screen with touch screen panel

- Conveyor equipped with polyurethane belts with steel wire core

- Vertical timing belts with a special outer cover manage the glass inside the machine

- High precision and pressurized electro-spindles (up to 12000 RPM)

- Drilling process carried out by two opposed spindles

- Air cooling system

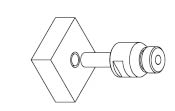

- The movement of the spindles is carried out using ball-guides and screw which are protected by pressurized coverings

- The high-precision positioning and driving is carried out using brushless motors

- Glasses are held in place automatically during drilling

- Automatic tool changing

- Program coding can be done by the machine from ISO Editor or modifying the stored library

- Storing programs in memory

- Data download/upload by means of USB key or net interface

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

Especially suitable for medium/big glass companies for the production of mirrors, shelves for furniture, laminated glass, table tops, household appliances and doors

Datasheet

| thickness ranging | 3/19 mm | |

| minimum dimension | min 200x600 mm max 3.200x6.000 mm | |

| max load | 800 Kg | |

| height of work surface | 700 mm | |

| total capacity | 15 kW | |

| tank capacity | 125 l | |

| air consumption | 600 Nl/min | |

| forward speed | 0/10 m/min. | |

| overall weight | 4.000 Kg | |

| Ø max utensile | 85 mm | |

| max drilling distance | 2.000 mm |

| thickness ranging | 3/19 mm | |

| minimum dimension | min 200x600 mm max 3.200x6.000 mm | |

| max load | 800 Kg | |

| height of work surface | 700 mm | |

| total capacity | 15 kW | |

| tank capacity | 125 l | |

| air consumption | 600 Nl/min | |

| forward speed | 0/10 m/min. | |

| overall weight | 4.000 Kg | |

| Ø max utensile | 85 mm | |

| max drilling distance | 2.000 mm |

| thickness ranging | 3/19 mm | |

| minimum dimension | min 200x600 mm max 3.200x6.000 mm | |

| max load | 800 Kg | |

| height of work surface | 700 mm | |

| total capacity | 15 kw | |

| tank capacity | 125 l | |

| air consumption | 600 Nl/min | |

| forward speed | 0/10 m/min. | |

| overall weight | 4.500 Kg | |

| Ø max utensile | 85 mm | |

| max drilling distance | 2.500 mm |

| thickness ranging | 3/19 mm | |

| minimum dimension | min 200x600 mm max 3.200x6.000 mm | |

| max load | 800 Kg | |

| height of work surface | 700 mm | |

| total capacity | 15 kW | |

| tank capacity | 125 l | |

| air consumption | 600 Nl/min | |

| forward speed | 0/10 m/min. | |

| overall weight | 4.500 Kg | |

| Ø max utensile | 85 mm | |

| max drilling distance | 2.500 mm |